Custom Weighing Systems: Hardware and Software Integration for Factories and Cooperatives

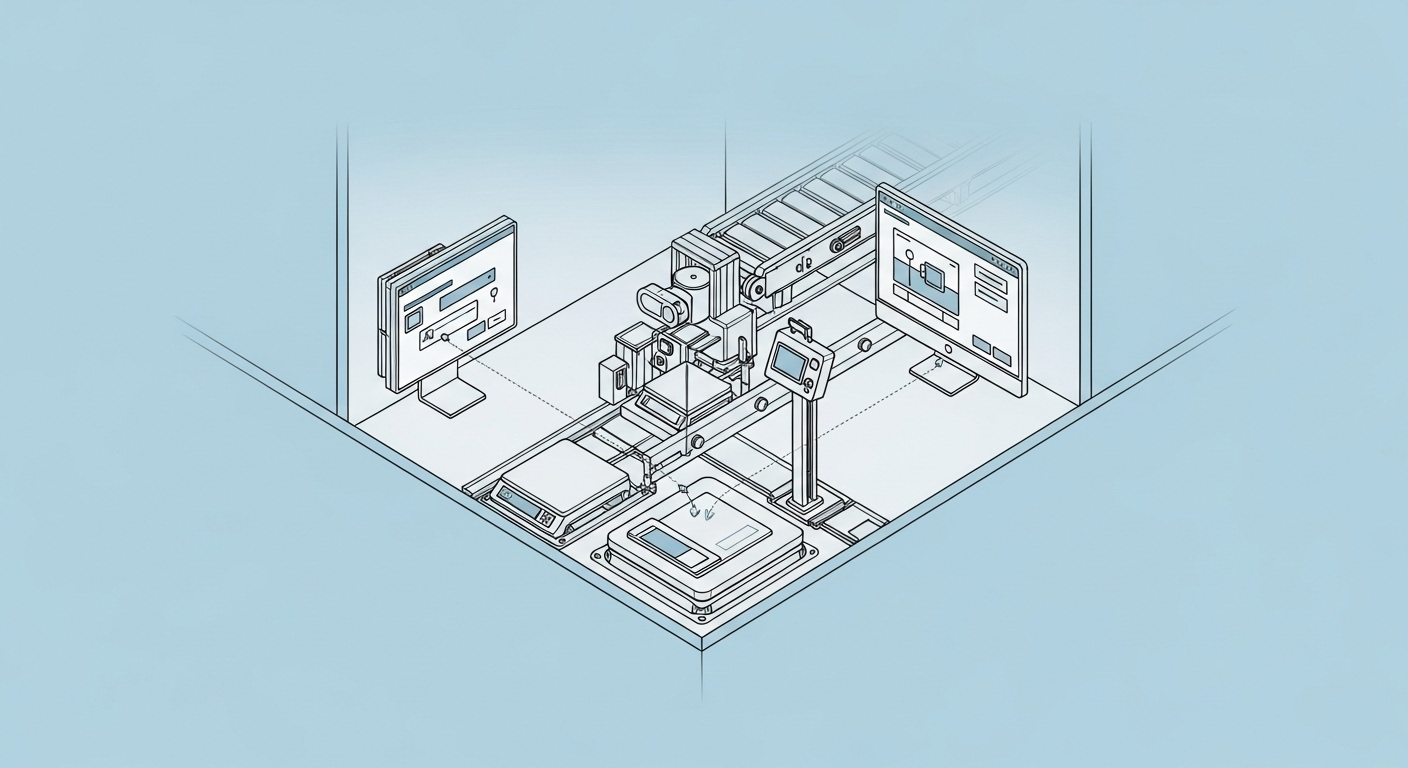

In manufacturing, agriculture, and logistics, the accuracy and integrity of weight measurements are non-negotiable. Generic, standalone weighing scales no longer meet the demands of modern operations. Custom Weighing Systems represent the next evolution, integrating specialized weighing hardware with bespoke software to create an end-to-end solution perfectly tailored for the unique processes of factories, processing plants, and agricultural cooperatives.

This holistic approach enhances operational efficiency, improves inventory control, and—crucially—protects against revenue loss due to fraud.

The Core: Hardware Integration and Specialization

A custom system starts with hardware designed for the specific industrial environment, seamlessly integrated into the overall process flow.

The foundation is built upon industrial scales (truck scales, platform scales, bench scales) that are robust, reliable, and capable of constant, high-volume operation.

Weighing Scale Tampering Guard: Ensuring Integrity

Integrity of measurement is paramount. The inclusion of the Anti-Tamper Guard transforms a scale from a measurement tool into a secure, monitored asset.

- Universal Security: This guard provides a universal security solution that can be integrated with existing commercial scales.

- Fraud Detection: It instantly detects physical tampering, such as when the calibration housing is opened, or when the calibration function is digitally enabled.

- Real-Time Alerts: Provides instant alerts via a dedicated app, SMS, or email, allowing management to intervene immediately.

- GPS Tracking: Offers real-time GPS tracking of the scale’s location, critical for mobile or distributed operations.

The Brain: Software Tailored for Process Optimization

The true value of a custom system lies in its integrated software platform, which turns raw weight data into actionable business intelligence.

| Feature | Factory Application | Cooperative Application |

|---|---|---|

| Inventory Management | Automatically updates raw material stock levels after goods-in weighing. | Tracks the specific yields and grades of produce delivered by each farmer. |

| Data Synchronization | Links scale data to ERP/MES systems for real-time production analysis. | Integrates with member databases to ensure accurate payment based on weight records. |

| Quality Control | Captures weights against quality specifications, flagging deviations instantly. | Records moisture content or foreign material alongside weight for quality grading. |

| Reporting | Provides auditable trails for regulatory compliance and loss prevention. | Generates detailed member statements and annual contribution reports. |

Mobility and Data Collection: The Field Link

Data integrity must be maintained even when measurements are taken outside the main plant. Durable, powerful mobile devices are essential for this purpose.

SWELL V760 Personal Digital Assistant (PDA)

The SWELL V760 is the ideal tool for field operators and factory floor staff who need to record data, conduct checks, or manage inventory remotely.

- Rugged Reliability: Built to endure industrial conditions with a MIL-STD-810G shockproof and IP68 waterproof rating.

- High Performance: Runs on Android 13 with an octa-core CPU, 8GB RAM, and 128GB storage, capable of running complex, custom inventory apps.

- Seamless Connectivity: Utilizes 4G LTE, dual-band Wi-Fi, and multi-system GPS to ensure continuous, reliable data transfer back to the central custom weighing platform.

Custom Weighing Systems are an essential investment for factories and cooperatives operating on tight margins where accuracy and process control are critical. By combining secure, high-precision hardware (like anti-tamper guarded scales) with bespoke, integrated software and rugged mobile tools, these systems not only streamline operations but also create a fortress around data integrity, ensuring fair trade and maximum profitability.