Revolutionizing Vehicle Weighing with Intelligent, Unmanned Systems

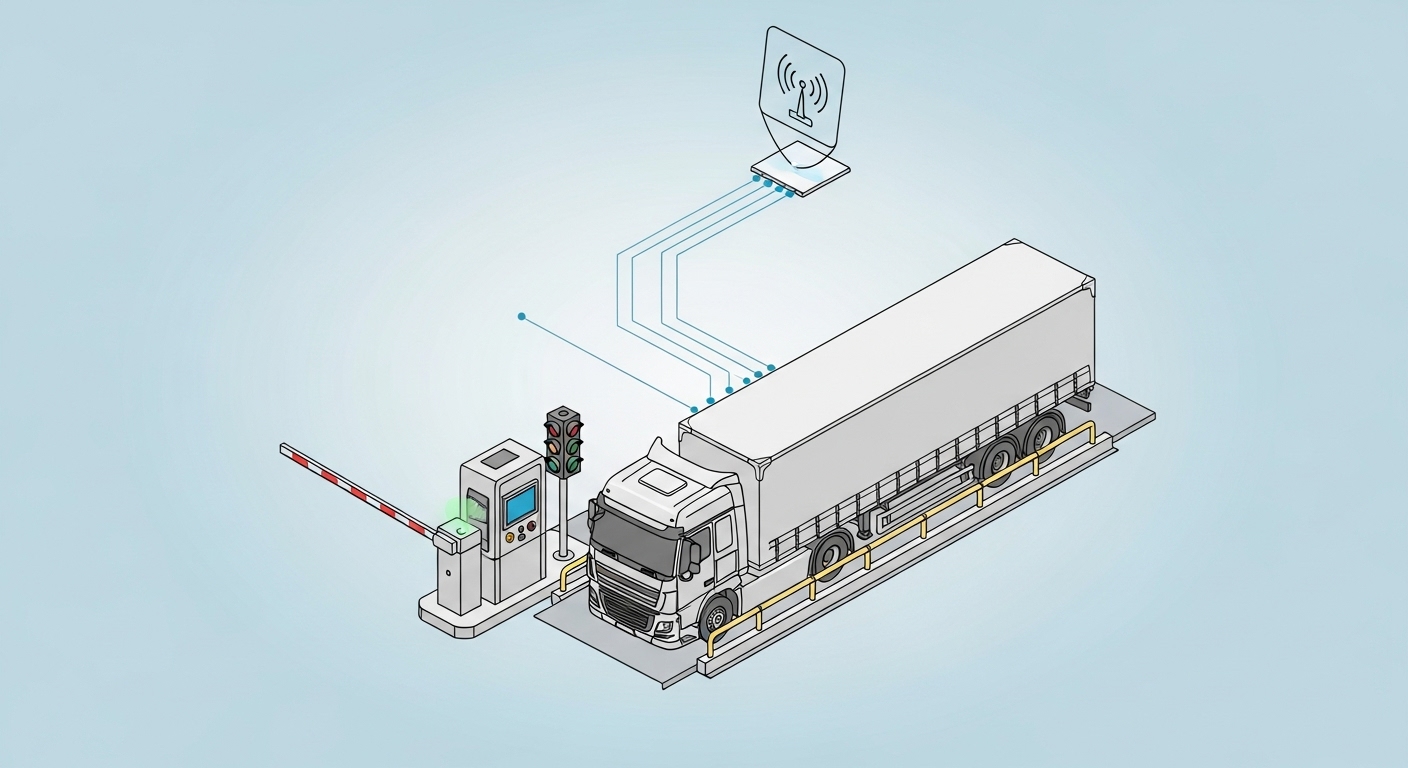

In modern industrial and logistics operations, ensuring the accurate, secure, and efficient measurement of vehicle weight is paramount. The traditional manned weighbridge is increasingly being replaced by Weighbridge Automation, an intelligent, unmanned, or semi-automated solution that uses advanced technology to streamline the entire process.

This shift is driven by the Vehicle Intelligent Weighing Management System, a networked solution that enhances efficiency, boosts data security, and actively combats fraud through sophisticated integration of hardware and software.

Features and Capabilities of the Intelligent Weighing Management System

Advanced Data Security and Network Control

The foundation of the system is its Centralized Client/Server (C/S) Management Software. This architecture allows for networked operation and provides good scalability, making it easy to add more weighbridges to the system as a business grows.

- Multi-Level User Authority: To ensure data integrity and accountability, the system employs a multi-level user authority design. System administrators can precisely assign different levels of access and operational permissions to individual users, safeguarding sensitive data.

- Real-Time Management: All weighing data is collected and managed in real time, allowing for immediate inquiry and efficient centralized management.

Intelligent Traffic and Process Management

Automation replaces manual oversight with integrated technology, ensuring an orderly and secure weighing sequence:

- Intelligent Management with RFID: The core of the unmanned process is the use of RFID cards (electronic tags) issued to vehicles. The system automatically reads the card upon arrival to retrieve and input key information (such as vehicle number and cargo name), dramatically streamlining the weighing process and eliminating manual data entry errors.

- Traffic Control Integration: An I/O controller manages all peripheral equipment, including barrier gates and traffic lights, to regulate vehicle flow, ensuring an orderly and safe procedure.

- Automated Barriers: Automatic barrier gates are positioned at the entrance and exit, serving to regulate flow and enforce orderly weighing procedures.

Fraud Prevention and Accuracy Guardrails

The intelligent system actively monitors the process to ensure accuracy and prevent common forms of weighing fraud:

- Infrared Vehicle Detection: Multi-beam infrared photoelectric switches are installed to detect any improper positioning. If a vehicle’s tires exceed the boundary of the weighbridge platform, the system will suspend the weighing process and trigger an alarm.

- Tare Alarm Function: The system is equipped with a specific tare weight alarm. If a vehicle’s current tare weight exceeds a pre-set acceptable range, the system immediately alerts the operator, acting as a crucial defense against fraudulent practices.

Communication and Documentation

Even in an unmanned system, necessary communication and documentation are automated:

- Integrated Voice System: An on-site voice system, using a microphone and outdoor waterproof speakers, automatically broadcasts instructions to drivers and allows staff in the weighing room to directly communicate with drivers on-site if necessary.

- Video Surveillance: For security and auditing, the system integrates with video surveillance cameras at both the entrance and exit to monitor vehicles, capture license plates, and store video footage for later review.

- Automatic Bill Printing: Upon the successful completion of the weighing process, the system automatically generates and prints a bill for the driver to collect.

Weighbridge automation, powered by the Vehicle Intelligent Weighing Management System, marks a significant technological leap. By integrating RFID, centralized software, and advanced detection features, organizations can move toward a completely unmanned or semi-automated operation, resulting in faster throughput, lower labor costs, and a high degree of confidence in the security and accuracy of their logistical data.